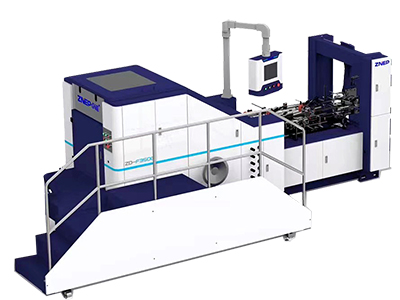

Block Bottom Bag Making Machine (Side Clamp Bottom Opening)

The block bottom bag making machine is specially designed for the production of various kinds of paper bags including recycled paper bags, paper food bags, paper shopping bags, etc. The machine can use printed roll paper as raw material for the automatic production of paper bags in various sizes.

| Model | ZD-F230 |

ZD-F350 |

ZD-F450 |

| Paper roll width | 290-790 mm | 420-1090 mm | 630-1370 mm |

| Max. diameter of paper roll | Ø1500 mm | Ø1500 mm | Ø1500 mm |

| Inner diameter of paper roll | Ø76mm | Ø76 mm | Ø76 mm |

| Paper gram | 50/65-150g/m² | 60-150g/m | 70-150g/m² |

| Finished bag width | 80-230mm | 130-350mm | 220-450mm |

| Paper tube length | 220-470mm | 260-530mm | 280-630mm |

| Bag bottom width | 50-150mm | 65-180mm | 80-220mm |

| Max. production speed | 240 bags/min | 220 bags/min | 200 bags/min |

| Working air pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa |

| Total power | 380V3P4L 15kW | 380V3P4L 15kW | 380V3P4L 18kW |

| Weight | 9000 kg | 10000 kg | 11000 kg |

| Overall dimensions | 9400*3600*2000 mm | 1000*3700*2100 mm | 10500*3800*2200 mm |

Each fully automatic block bottom bag making machine is equipped with a Mitsubishi electrical control system to provide stability and easy operation. Compared with sheet fed paper bag making machines, the block bottom bag making machine is more environmentally friendly and economically affordable because it can create high-quality bag from thin paper based on flexo printing. These machines operate with high performance and energy efficiency that is sustainable for future endeavors.

-

-

FEEDING UNIT

The roll paper fixed on the air expanding mandrel can be fed by swing arm which is equipped with lifting hydraulic system. With an alarm function, the feeding unit will sound alarm when there is no paper feeding. Improved surface smoothness of the paper during the feeding is achieved due to the web guide and uniform tension control. Paper rolls can be easily changed by pressing a button.

-

-

BAG FORMING UNIT

Material in the form of a tube is fed from the unwinder. The machine will form paper with patches and side glue into the tube; and cut into separate pieces based on the settings. The tube is then sealed and a cut is made below the seal, so that a tube with the bottom closed is formed.