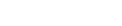

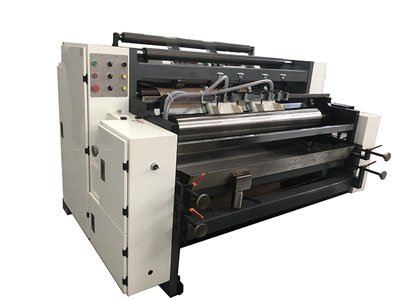

Window Patching Block Bottom Bag Making Machine

We specially designed this bag making machine to produce various kinds of paper bags with a clear window mainly for food use. The equipment uses printed or blank roll paper as raw material for the automatic production of paper bags of various sizes.

| Model | ZDF-KM190 |

ZDF-KM350 |

| Roll paper width | 280-650mm | 420-1090mm |

| Max. diameter of roll paper | 1500mm | 1500mm |

| Core diameter of roll paper | 76mm | 76mm |

| Paper gram | 50-150g | 60-150g |

| Finished bag width | 80-190mm | 130-350mm |

| Paper tube length | 190-370mm | 260-530mm |

| Bag bottom width | 50-110mm | 65-180mm |

| Film gram | 0.02g-0.05g | 0.02g-0.05g |

| Window width | 20-120mm | 20-200mm |

| Window length | 20-160mm | 20-200mm |

| Max. production speed | 180/220 pcs/min | 150/180 pcs/min |

| Total power | 28kw | 28kw |

| Weight | 12000kg | 13800kg |

| Overall dimensions | 12600*2000*1800mm | 13500*3300*2000mm |

The ZNEP window patching block bottom bag making machine strictly controls each manufacturing process when producing high quality paper bags from plain or pre-printed paper roll. The bag making machine features a Mitsubishi electrical control system and operates under precision servo motor control to ensure high stability and easy operation. It features high production efficiency which is always a perfect choice for reducing labor and manufacturing costs. Compared with sheet fed paper bag making machines, this equipment is eco-friendlier and more economical as it can produce high quality bags from thin paper.

- Roll Feeding

- Window Cutting

- Patch Gluing

- Film Pasting

- Side Gluing

- Tube Forming

- Tube Cut-off

- Creasing

- Bottom Folding

- Bottom Gluing

- Bottom Forming

-

-

FEEDING UNIT

The roll paper fixed on the air expanding mandrel can be fed by swing arm which is equipped with lifting hydraulic system. With an alarm function, the feeding unit will sound alarm when there is no paper feeding. Improved surface smoothness of the paper during the feeding is achieved due to the web guide and uniform tension control. Paper rolls can be easily changed by pressing a button.

-

-

PATCHING UNIT

This unit adopts an abreast double-knife to ensure the synchronization of the film patch or paper patch. Gluing, traction and cutting of the patch rolls are all controlled by servo motors. After putting the glue on desired locations and folding by a pneumatic roller, the system realizes the automatic functions of paper feeding, conveying, window gluing, film slitting and patching to produce the ready paper bags through a second roller mechanism.

-

-

BAG FORMING UNIT

The product is initially formed using the paper, and patches and side glue are attached to the tube. Afterwards, the resulting textile is cut into separate pieces based on the settings. Lastly, these separate tubes would be sent to the drum. The four corners would be opened, then the bottom is glued, sealed, and formed into a square shape.