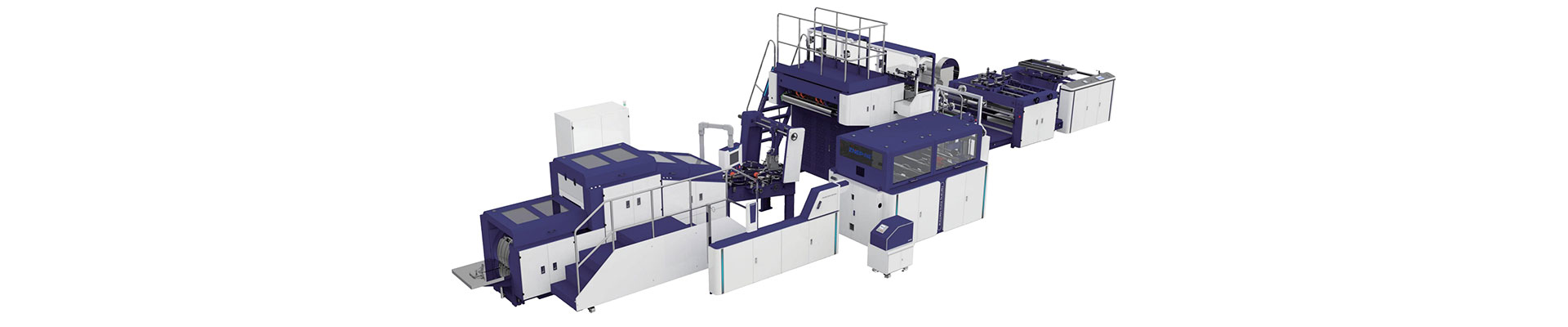

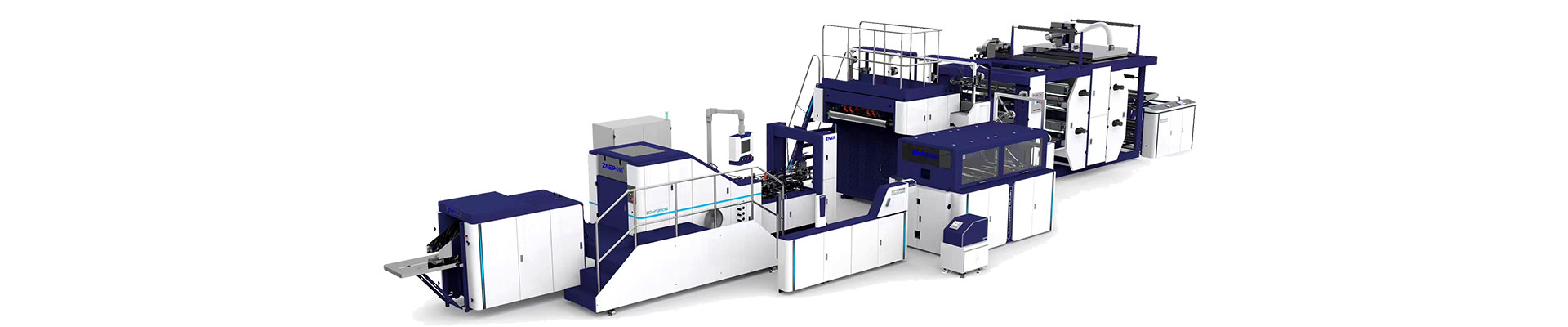

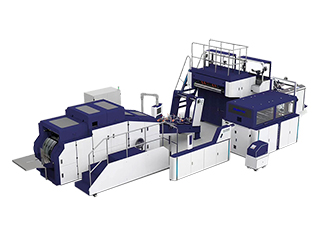

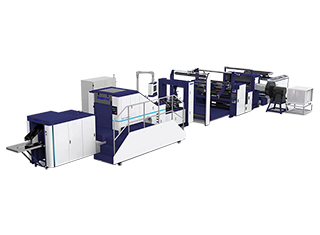

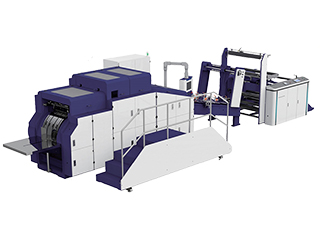

A wide range of paper bags with different specifications can be produced by our machine, including block bottom bags, window patching bags, twisted handles bags, flat handles bags, and flat satchel bags. Our bag making machines operate automatically to process paper bags perfectly and efficiently. The high production capacity and low operating costs will completely satisfy your needs for large-scale bag production.

Advanced processing equipment and technologies are adopted to guarantee the high strength and excellent durability of the parts of our bag making machines.

Each of our paper bag making machines is developed and manufactured to consistently meet strict standards in operational safety, material selection, production processes, and structural design. Through years of continuous refinement and technical upgrades, they deliver reliable performance in operation, maintenance, durability, production efficiency, and stability.

- All gear and chain drive areas are equipped with protective safety covers.

- Each main operating station includes an emergency stop button for immediate shutdown when needed.

- If any protective cover door is opened during operation, the machine stops automatically to prevent accidents.

- A warning alarm is triggered when raw material is exhausted during production.

- The gears our paper bag machines are equipped with are made with high-strength 20CrMnTi alloy steel.

- The main frame base and side panels are manufactured using ductile iron castings with an integrated structure to ensure greater strength.

- Traction rollers, separating rollers, and conveyor rollers are made of hard alloy materials for extended service life.

- Pressure rollers in the tube forming section are manufactured with imported polyurethane to maintain stable performance.

- The cross-cutting knives are made of imported high-speed steel to achieve precision cutting.

- All adjustment points are clearly marked with scales to help operators make precise settings easily.

- Areas for pressure regulation are equipped with air or pressure gauges, making it simple to monitor and adjust parameters as needed.

- If a bag jam occurs, clearing the obstruction from the exterior is quick and convenient.

- Each paper bag making machine is manufactured with a structural lifespan of up to 30 years, including the frame, side panels, hubs, and cast components that undergo precise stress-relief treatments to ensure dimensional stability over time.

- The main assemblies, such as gears, fixtures, spindles, and customized components, are specified for reliable operation and a service life of up to 20 years under standard working conditions.

- Main wear parts, including forming plates, traction rollers, separation rollers, small hubs, and primary shafts, are designed for consistent performance with an expected lifespan of up to 10 years.