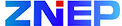

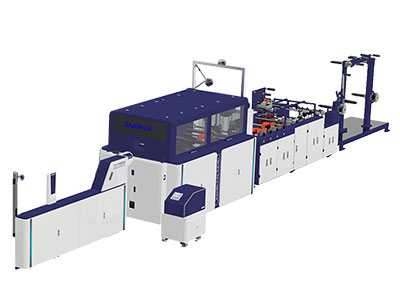

Automatic Paper Bag Making Machine with Flap and Twisted/ Flat Handles

This paper bag making is specifically designed for the automated, inline production of paper shopping bags with flat and twisted rope handles. The handles, which are created by the handle making unit, are delivered to the main machine where they are cut and pasted onto the paper. This paper bag machinery can form the paper bag in one process from either plain or pre-printed paper. It includes features such as window cut and waste suction, gluing and pasting, easy tearing line perforation, pre-cutting at the rope position, gluing for handle patch and pasting, side gluing, tube forming and cutting, bottom creasing and gluing, and forming to bag collection.

In addition, our paper bag making machines are equipped with Japanese servo motors, ensuring fast, stable operations and reducing the time needed for size adjustments. With its high precision, strong stability, easy maintenance, and efficient production capabilities, the paper bags equipment is an excellent choice for printing houses and paper bag manufacturers looking to produce top-quality bags with minimal effort.

| Model | ZD-FN380QT |

ZD-FN550QT |

| Paper roll width | 580-1270 mm | 630-1730 mm |

| Max. diameter of paper roll | Ø1500 mm | Ø1500 mm |

| Inner diameter of paper roll | Ø76 mm | Ø76 mm |

| Paper gram | 60/80-150 g/m² | 80/90-150 g/m² |

| Finished bag width | 200-380 mm | 220-550 mm |

| Paper tube length | (230+flap height)-(655mm including flap & handle height) | (380+flap height)-(770mm including flap & handle height) |

| Bag bottom width | 75-240 mm | 80-300 mm |

| Flap height | 30-80 mm | 30-80 mm |

| Releasing paper width | 15-35 mm | 15-35 mm |

| Flap paper gram | 50-100 g/m² | 50-100 g/m |

| Max. production speed | 120 bags/min | 110 bags/min |

| Total power | 380V 3P4L56 kW | 380V 3P4L 56kW |

| Weight | 27000 kg | 29000 kg |

| Overall dimensions | 15800*6900*3400 mm | 17600*7200*3500 mm |

| Twisted rope handle | Q3 | Q4 | Q5 |

| Handle rope height | 90-120 mm | 90-120 mm | 90-120 mm |

| Handle rope diameter | Ø3-6 mm | Ø3-6 mm | Ø3-6 mm |

| Handle patch length | 152 mm | 190 mm | 190 mm |

| Handle patch width | 35-50 mm | 35-50 mm | 35-50 mm |

| Handle rope distance | 76 mm | 95 mm | 101 mm |

| Paper patch roll diameter | Ø1200 mm | Ø1200 mm | Ø1200 mm |

| Paper patch roll width | 70-100 mm | 70-100 mm | 70-100 mm |

| Paper patch gram | 80-150 g/m² | 80-150 g/m² | 80-150 g/m² |

| Flat handle | B1 | B2 |

| Paper gram for handle | 100-130 g/m² | 100-130 g/m² |

| Flat handle width | 12 mm | 15 mm |

| Flat handle height | 100 mm | 100 mm |

| Flat handle distance | 76 mm | 95 mm |

| Diameter of reel paper for handle | Ø1200 mm | Ø1200 mm |

| Paper patch gram | 100-150 g/m² | 100-150 g/m² |

| Paper patch roll diameter | Ø1200 mm | Ø1200 mm |

| Handle patch length | 152 mm | 190 mm |

| Handle patch width | 35-50 mm | 35-50 mm |

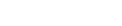

- Paper Roll Feeding

- Window Cutting/V Cutting/Easy-Tear Line

- Glue Spraying

- Release Liner Pasting

- Perforating

- Handle Gluing

- Handle Pasting

- Side Gluing

- Tube Forming

- Leftover Cutting

- Bottom Folding

- Bottom Gluing

- Bottom Sealing

-

-

Feeding Unit

The feeding unit is designed to streamline the paper feeding process into the machines. It starts with paper reel securely mounted on an air expanding shaft, which is then fed into the machine using a swing arm equipped with a hydraulic lifting system. This unit is enhanced with several key features: an alarm function that alerts when paper feeding is required, an automatic web guide system for improved paper surface smoothness, and a uniform tension control to ensure consistent paper feed. Additionally, changing paper rolls is simplified through an easy-to-use button control, making the process straightforward and efficient.

-

-

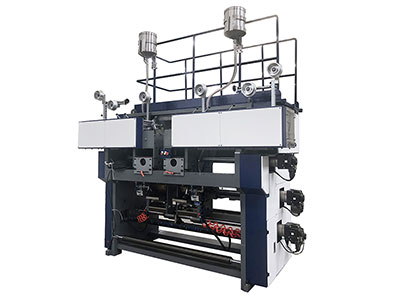

Handle Making Unit

The handle making unit start the handle making process by simultaneously feeding two rolls of patch paper and one roll of paper rope. The paper rope is then adhered to the patch paper using a combination of water-based and hot melt glue. Following this, a compression device ensures the handles are firmly attached and aligned. The final step involves cutting the handles to the required length and transferring them to the handle patching unit, ready for the next stage of bag assembly.

-

-

Handle Pasting Unit

The handle pasting unit in our paper bag making machinery is a key component for attaching handles. Once the handle strips are cut to size, they are precisely positioned onto the designated area of the paper bag. The unit applies a water-based adhesive to bond the handle to the bag securely. Following this, the handles are firmly pressed onto the bag surface to ensure a strong attachment. This process is completed before the bag is sent to the forming unit for pre-creasing, preparing it for the final production steps.

-

-

Bag Forming Unit

The bag forming unit plays a crucial role in shaping the final product. It begins by forming the glued paper, complete with handles, into tubes. These tubes are then precisely cut into individual pieces as per the set requirements. The next stage involves transferring these tubes to a drum mechanism, which opens them into a four-cornered shape, aided by a vacuum suction system. Following this, the bottom of the bag is glued, sealed, and formed into a square shape. The final step involves compressing and delivering the finished bags out of the machine.

-

-

Bag Collecting Unit

The bag collecting unit handles the final stage of the production process. It compresses the formed bags to ensure a neat finish and then smoothly outputs the finished bags. An integral part of this unit is the counting system, which accurately displays the total number of bags produced, providing valuable data for production tracking and quality control.